Over the past almost two decades, Automation Alternatives’ unique liquid dispensing equipment has served a wide spectrum of industries from electronics and medical device manufacturing to automotive and solar module manufacturing.

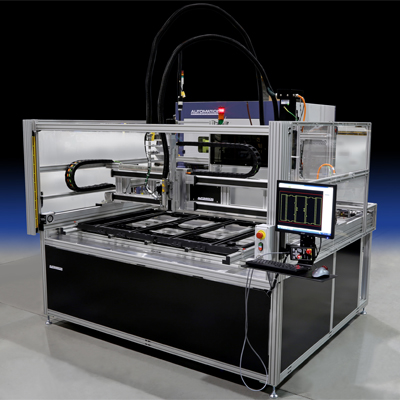

The offerings include both standalone platforms and fully automated systems integrated into full-blown automatic processes. In the latter case, complementary systems such as automated loading and unloading, inline inspection, pass and fail sorting, etc., can be supplied as part of a complete turn-key package.

Many innovative and proprietary solutions we have offered to our customers have empowered them to successfully implement their challenging processes, stay ahead of their competition and improve their productivity and profitability.

Our expertise covers handling a wide range of materials from very low viscosity to extremely high viscosity both room-temperature and hot-melt materials.

Our dispensing equipment includes two categories of dispensers, FlexDispense and FlexSeal. Equipment of each category is designed not only based on the properties of the materials being dispensed, but also with the needs and comfort level of the users in mind. This will include machine design, special features and controls and interfaces.

FlexDispense Systems

FlexDispense systems is a flexible powerful dispensing system that can lend itself to many processes and is a valuable tool for many industries.

FlexSeal Systems

FlexSeal systems is a unique system specifically designed for edge sealing of the solar modules. It has tremendous capability in handling extremely high viscosity materials such and butyl that is used in solar module manufacturing industry. It also has a proprietary articulating nozzle system that allows the system to place down very precise ribbon (tape) of material very cost-effectively to replace taping.

Our application engineers will be more than happy to help our customers select the best and most cost-effective solution for their applications. Contact us today for more information!