FlexDispense by Automation Alternatives is a family of liquid dispensing systems for precise and challenging dispensing applications. The applications include dispensing of single or twopart room-temperature, hot-melt or UV-curable materials, from very low to extremely high viscosities.

FlexDispense by Automation Alternatives is a family of liquid dispensing systems for precise and challenging dispensing applications. The applications include dispensing of single or twopart room-temperature, hot-melt or UV-curable materials, from very low to extremely high viscosities.

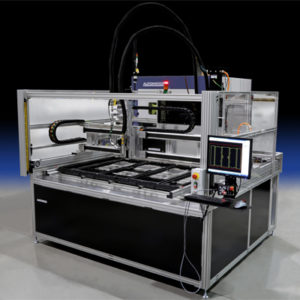

FlexDispense come in different sizes from compact 24”x24”working area to large custom formats to suit any application. The system can be standalone or inline with many custom automated features to suit literally any processes.

Applications

FlexDispense is an ideal solution for a variety of applications including precision dot dispensing for electronic industries, bead dispensing, gasketing, potting, windows and solar modules manufacturing, medical devices and automotive, where precise and controllable bead or dots of material is required.

FlexDispense can be standalone or customized to inline automated process lines with many options.

Materials

FlexDispense can perfectly handle a vast variety of materials from very low to very high viscosities, single part, two-part or hot-melt.

Software and Controls

FlexDispense is very easy-to-operate and is controlled by a powerful, user friendly software. Its integral industrial computer is pre-configured and loaded with all the necessary software. The system can easily create dispense patterns or import more elaborate patterns from CAD packages. PLC-based systems are also available for compatibility with balance-of-plant systems if required.

Vision System

FlexDispense can have optional vision systems for registration and verification and inspection of dispense patterns and profiles.

Material Delivery System

FlexDispense can be equipped with matching material delivery systems from small integral systems for mini applications to large single or tandem material delivery systems for large, high volume applications.

Material Handling

FlexDispense can easily be integrated into fully automated production lines. Also upstream and downstream material handling systems or complementary processes including loading and unloading conveyors, inline inspection, plasma treatment, marking systems, etc., can also be included as part of a turn-key package.