AUTOMATION ALTERNATIVES

YOUR AUTOMATIC CHOICE FOR INDUSTRIAL LASERS

OUR SOLUTIONS

LASER SYSTEMS

Automation Alternatives offers its laser processing equipment in two main categories; Metallic and Non-metallic material processing equipment. Equipment of each category is designed not only based on the properties of the materials being processed, but also with the needs and comfort level of the users in mind. This includes machine design and features as well as controls and interfaces.

LASER CONTRACT MANUFACTURING

Automation Alternatives has been providing laser contract manufacturing almost at the same time of introducing their laser processing equipment to the market. These services cover all aspects of laser processing including cutting, marking and welding for both metallic and non-metallic materials. These have been designed to help our customers in different industries in a variety of ways.

SUPPORT

Providing superior customer care including after sales support and services has always been our highest priority. Many returning customers attest to the importance and value of this service to the customers as well. Our comprehensive approach to customer service ensures that Automation Alternative customers enjoy many years of uninterrupted and productive use of their equipment.

OUR PRODUCTS

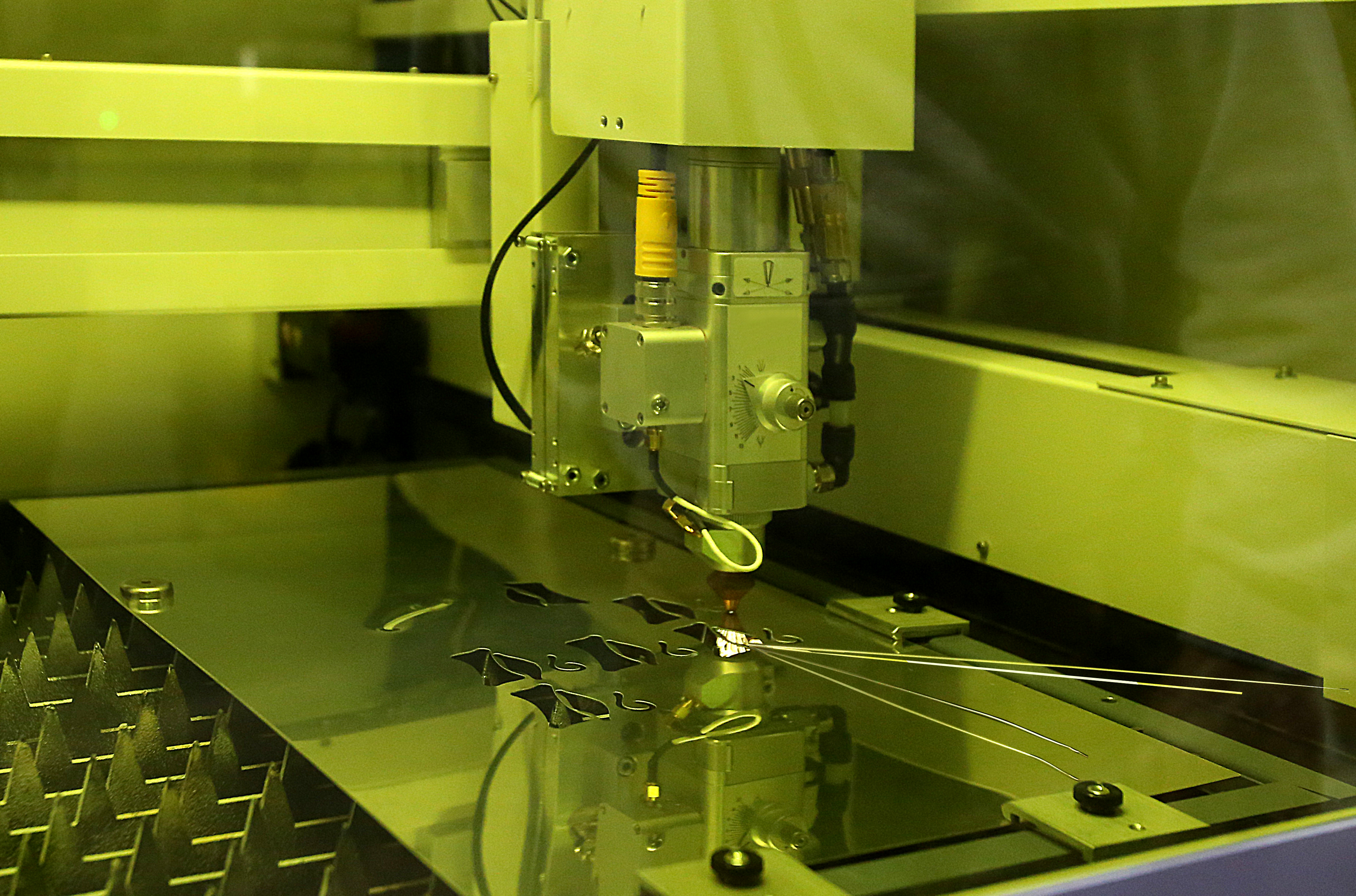

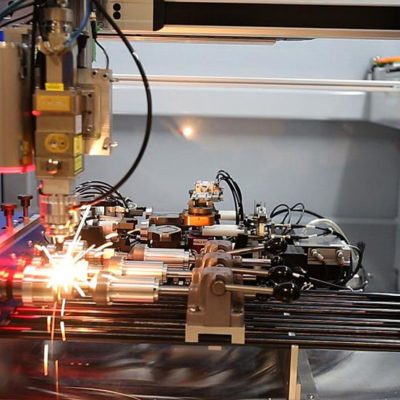

Metallic Material Processing Systems

Metallic Material Processing systems use fiber-laser technology and include laser cutting, welding and marking systems in different sizes and power levels.

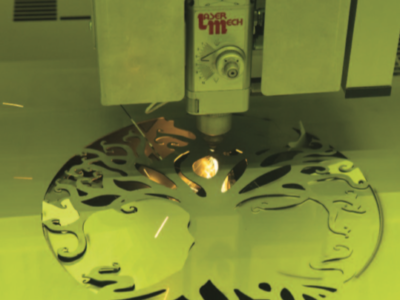

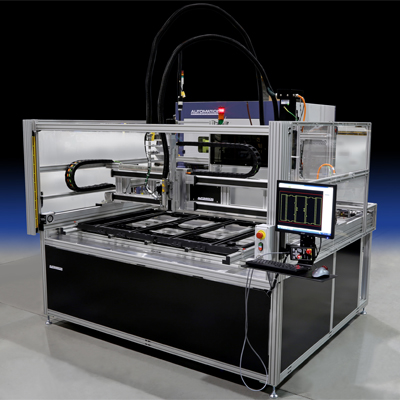

Non-Metallic Material Processing Systems

Non-Metallic Material Processing systems use CO2 and other technologies and will include cutting, marking and ablating systems in a variety of sizes and laser powers.

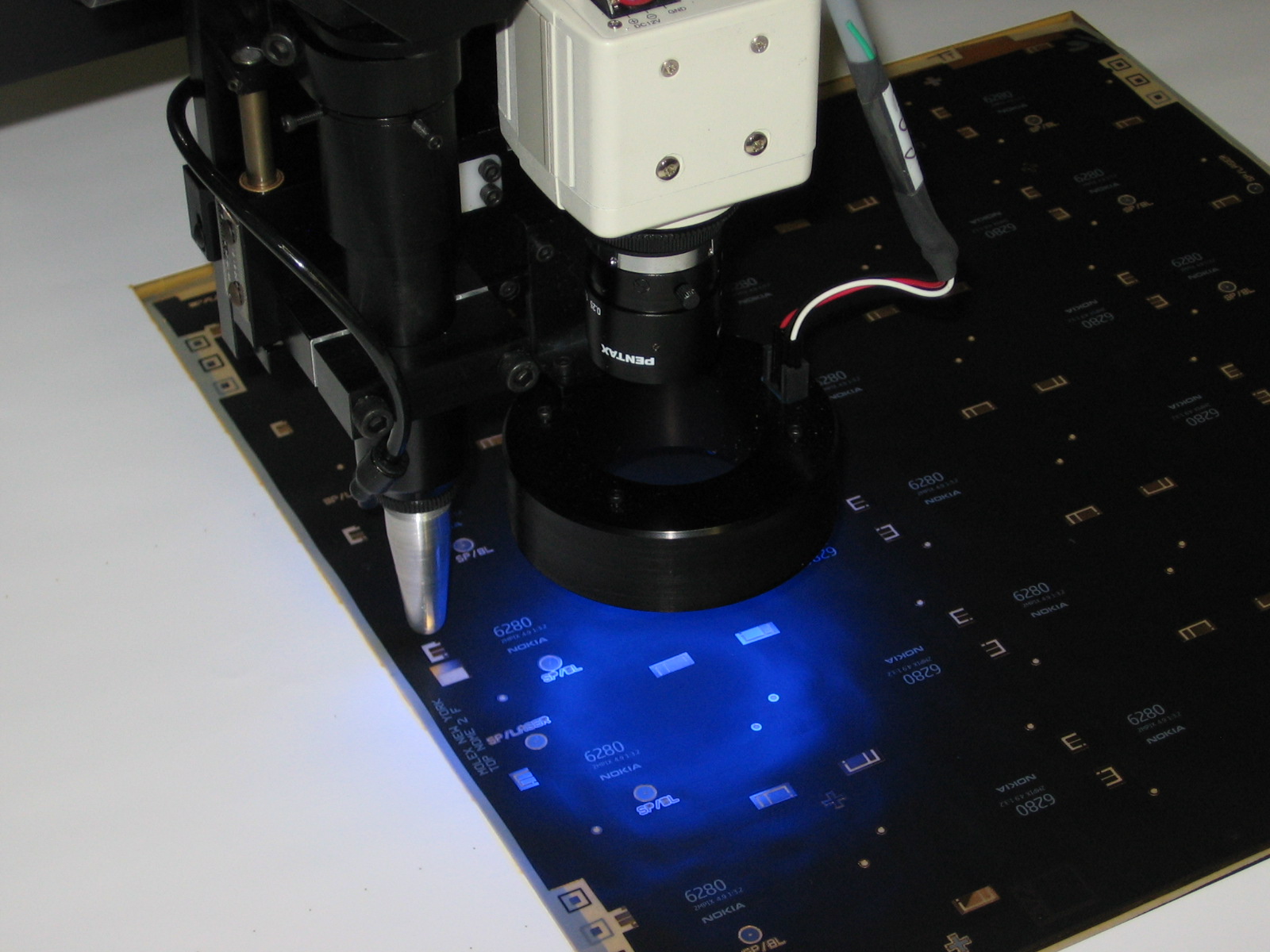

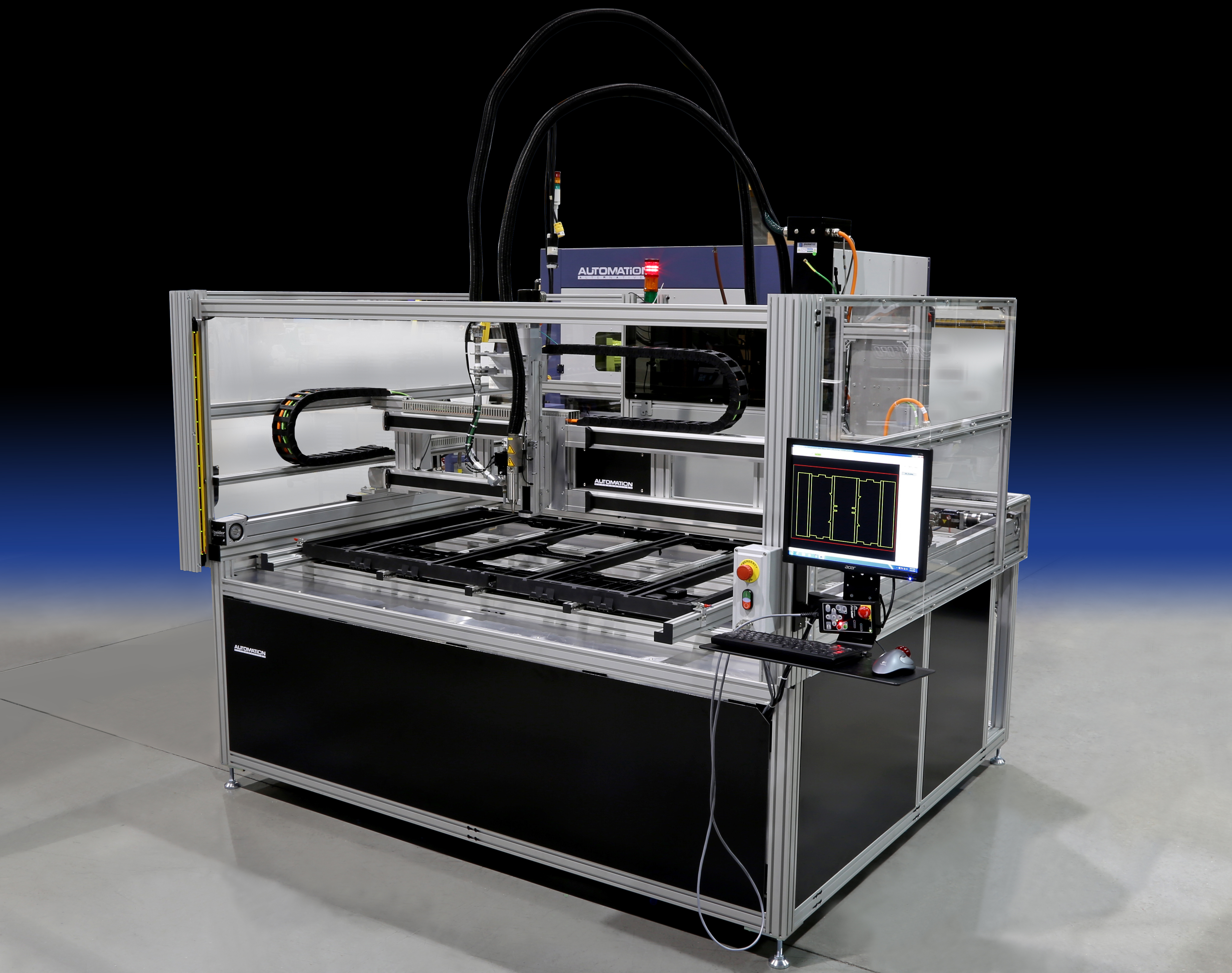

LIQUID DISPENSING SYSTEMS

Over the past almost two decades, Automation Alternatives’ unique liquid dispensing equipment has served a wide spectrum of industries from electronics and medical device manufacturing to automotive and solar module manufacturing.

ABOUT US

At Automation Alternatives our top priority is to work with our customers to help them define their specific technology requirements and design and deliver the most cost-effective solution available.

We offer a complete line of laser systems and services so we can match the right solution for your specific need and budget.

CASE STUDIES

The Smart Factory – Laser manufacturer engineers hardware and software to give fabricators custom building blocks

Zootility Co. – Entrepreneur ignites production throughput for stainless steel, razor- thin, wallet-friendly utility tools

CONTACT US

Phone

Telephone: 905-605-9200

Fax: 905-605-9400